How to Record QC Results and Feedback Using Kakobuy Spreadsheet

Quality Control (QC) is a critical aspect of cross-border sourcing, ensuring that products meet buyer expectations before shipment. When conducting QC inspections on the Kakobuy platform, properly documenting findings allows for efficient tracking and resolution of issues. Here's a step-by-step guide on utilizing the Kakobuy spreadsheet to record inspection results:

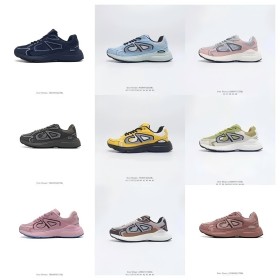

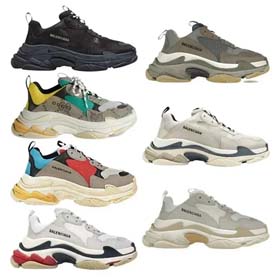

Step 1: Examine Key Product Attributes

- Appearance:

- Functionality:

- Completeness:

- Functionality:

Step 2: Log Findings in the Spreadsheet

Kakobuy's structured spreadsheet should include columns for:

| Field | Example Entry |

|---|---|

| Product ID/SKU | KB2024-WH-XL |

| Defect Category | Packaging damage |

| Severity Level | Minor (does not affect functionality) |

Pro Tip:

Create status fields with timestamps: By systematically documenting QC data in Kakobuy's spreadsheet, both buyers and sellers benefit from transparent communication, faster dispute resolution, and continuous quality improvement. Visit Kakobuy's official site

Step 3: Attach Visual Evidence

Step 4: Track Resolution Progress

Additional Optimization: